Exploring the seamless integration of Altium Auto Route into Automotive PCB Design opens up a world of possibilities for enhancing design processes. Let's delve into how this innovative tool revolutionizes automotive PCB design with precision and efficiency.

As we navigate through the key features, challenges, solutions, and best practices, you'll gain valuable insights into leveraging Auto Route for exceptional results in automotive applications.

Introduction to Altium Auto Route in Automotive PCB Design

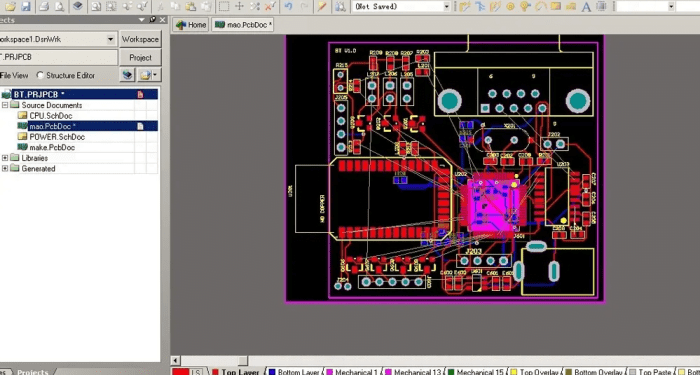

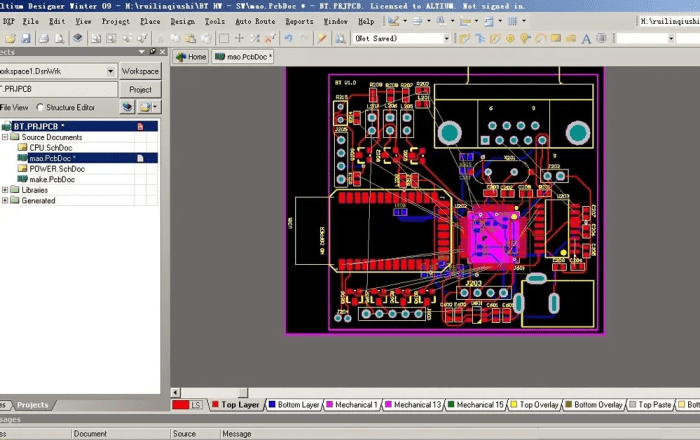

Altium Auto Route is a feature in PCB design software that automates the process of routing connections between components on a printed circuit board. It uses algorithms to determine the best paths for signal traces, power lines, and other connections, saving time and effort in the design process.

Integrating Auto Route into automotive PCB design is crucial due to the complexity and precision required in automotive electronics. By automating the routing process, engineers can ensure signal integrity, reduce electromagnetic interference, and optimize the layout for efficient manufacturing and assembly.

Significance of Altium Auto Route in Automotive PCB Design

- Optimizes signal integrity: Auto Route helps in creating optimal signal paths, reducing signal distortion and ensuring reliable communication between components in automotive systems.

- Reduces electromagnetic interference: By automatically routing traces with proper spacing and shielding, Auto Route minimizes EMI issues that could affect the performance of electronic components in a vehicle.

- Streamlines design process: Auto Route speeds up the design process by automatically generating routing solutions, allowing engineers to focus on other critical aspects of automotive PCB design.

Key Features of Altium Auto Route for Automotive PCB Design

When it comes to designing automotive PCBs, Altium Auto Route offers a range of key features that can significantly enhance efficiency and accuracy in the design process.

Automatic Routing

- Altium Auto Route automates the routing process, saving time and reducing the risk of human error.

- By automatically connecting components based on predefined rules, it ensures a more efficient design workflow.

Interactive Routing

- Allows for manual intervention in the routing process, giving designers more control over the final layout.

- Enables designers to optimize signal paths and avoid potential interference issues.

Design Rule Checking (DRC)

- Automatically checks the design against predefined rules to ensure compliance with industry standards and design requirements.

- Helps detect and correct errors early in the design process, improving overall accuracy.

Efficiency and Accuracy

- Altium Auto Route streamlines the routing process, leading to faster design iterations and shorter time-to-market.

- By reducing manual errors and ensuring compliance with design rules, it enhances the overall accuracy of the PCB design.

Performance and Reliability

- Compared to manual routing methods, Altium Auto Route offers improved performance in terms of speed and consistency.

- By automating repetitive tasks and optimizing signal paths, it enhances the reliability of the final PCB design.

Challenges and Solutions of Integrating Altium Auto Route in Automotive PCB Design

Integrating Altium Auto Route into automotive PCB design can present several challenges that designers may face. However, there are effective solutions and best practices that can help overcome these obstacles and optimize the design process.

Challenges Faced in Integrating Altium Auto Route

- Complex Routing Requirements: Automotive PCB designs often have intricate routing requirements due to the high density of components and the need for precise signal integrity.

- Sensitive Signal Paths: Ensuring signal integrity and minimizing electromagnetic interference (EMI) are crucial in automotive PCB design, which can be challenging to achieve with automated routing.

- Design Constraints: Automotive PCB designs have strict size, weight, and power constraints that need to be considered during the routing process, which can be difficult to manage with automated tools.

Solutions and Best Practices

- Pre-Planning and Constraint Definition: Before using Auto Route, it is essential to pre-plan the routing strategy and define design constraints to guide the automated routing process effectively.

- Manual Intervention: While Auto Route can automate the routing process, manual intervention is often necessary to ensure critical signal paths are routed appropriately and to address any design constraints.

- Iterative Optimization: Iteratively optimizing the routing process by running Auto Route multiple times with adjusted constraints can help achieve the desired design goals while minimizing errors.

Real-World Examples of Auto Route Benefits in Automotive PCB Design

One real-world example where Altium Auto Route has helped address complex design issues in automotive PCBs is in the optimization of high-speed signal paths for advanced driver assistance systems (ADAS). By using Auto Route in conjunction with manual intervention, designers were able to achieve precise routing of sensitive signals while meeting stringent EMI requirements.

Best Practices for Utilizing Altium Auto Route in Automotive PCB Design

When working on automotive PCB design, following best practices for utilizing Altium Auto Route can significantly improve the efficiency and quality of your designs. By implementing these tips and tricks, you can optimize the performance of Auto Route and achieve high-quality results in automotive applications.

Optimizing Auto Route Performance for Automotive Applications

- Begin by setting up design rules specific to automotive PCB requirements, such as signal integrity, thermal management, and EMI considerations.

- Utilize the interactive routing feature in Altium Designer to manually route critical traces before running the Auto Route function.

- Segment the PCB layout into different regions based on signal types to control trace lengths and reduce signal interference.

- Adjust the routing grid and routing topology settings in Altium Auto Route to fine-tune the routing paths for better signal integrity.

- Regularly review and optimize the design rules and constraints to ensure that Auto Route aligns with your project requirements.

Leveraging Auto Route for High-Quality Results in Automotive PCB Designs

- Use differential pair routing features in Altium Auto Route to maintain signal integrity and reduce crosstalk in automotive communication interfaces.

- Implement length tuning and impedance control for critical traces to meet automotive industry standards and ensure reliable performance.

- Employ the push and shove routing capabilities in Altium Designer to easily adjust routing paths and resolve design conflicts without compromising quality.

- Take advantage of the autorouter's optimization algorithms to efficiently route complex PCB layouts while adhering to design constraints.

- Perform design rule checks and signal integrity analysis after running Auto Route to validate the layout and address any potential issues early in the design process.

Epilogue

In conclusion, Altium Auto Route stands as a game-changer in the realm of automotive PCB design, offering a blend of advanced features and practical solutions. By mastering the best practices discussed, you're poised to elevate your design outcomes to new heights.

Helpful Answers

How does Altium Auto Route enhance efficiency in automotive PCB design?

Altium Auto Route streamlines the routing process, automating connections and optimizing signal paths, leading to faster design completion.

What are the common challenges when integrating Altium Auto Route into automotive PCB design?

Some challenges include ensuring proper signal integrity, managing component placement, and addressing design constraints effectively.

Can Altium Auto Route be used for complex automotive PCB designs?

Yes, Altium Auto Route excels in handling intricate designs by providing smart routing solutions and advanced optimization capabilities.